Friction in Pipes

Objective:

To determine the friction in pipes.

Apparatus used:

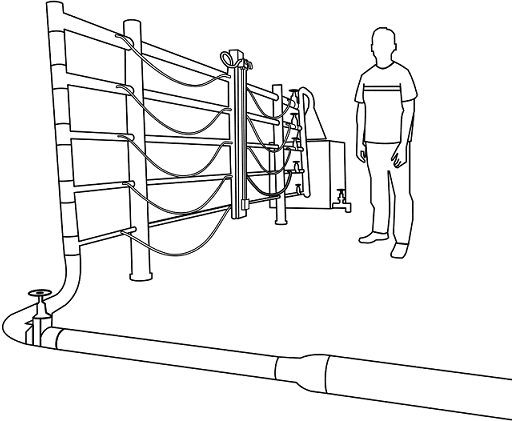

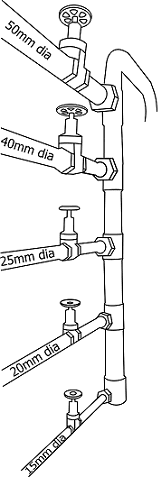

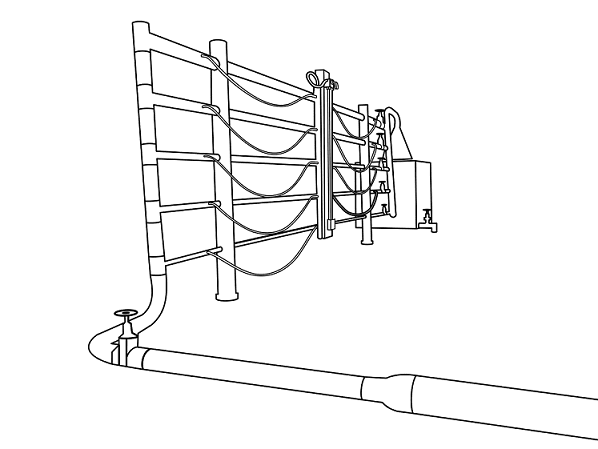

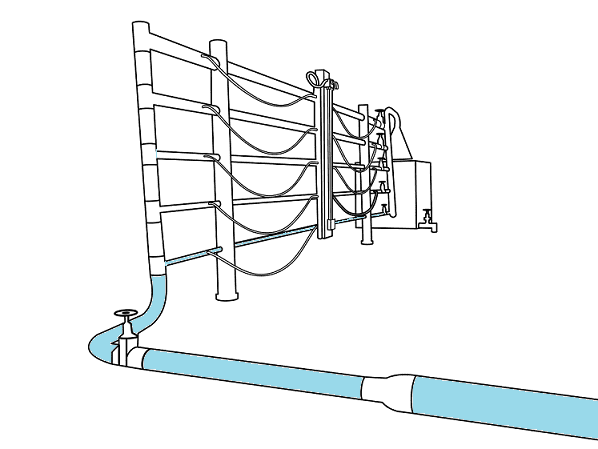

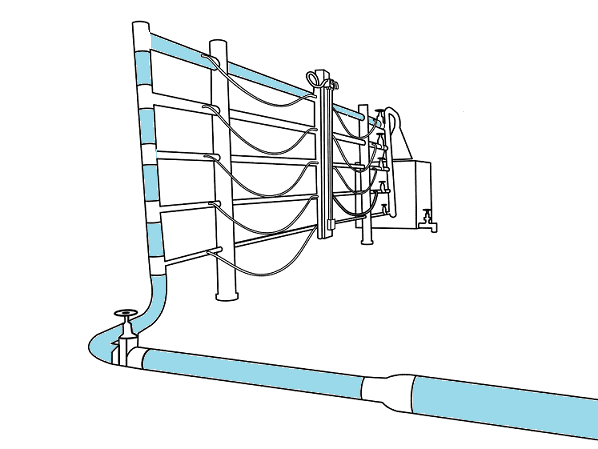

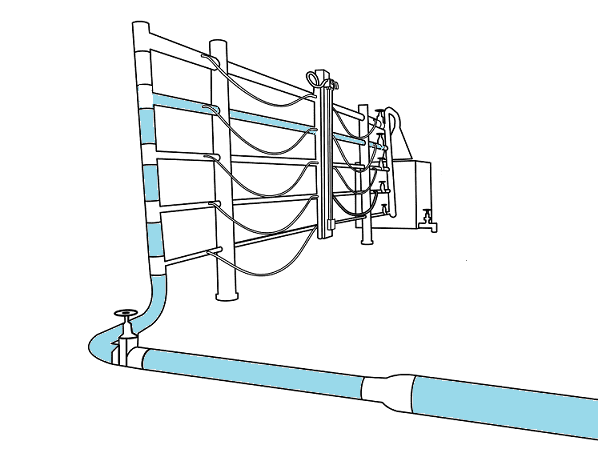

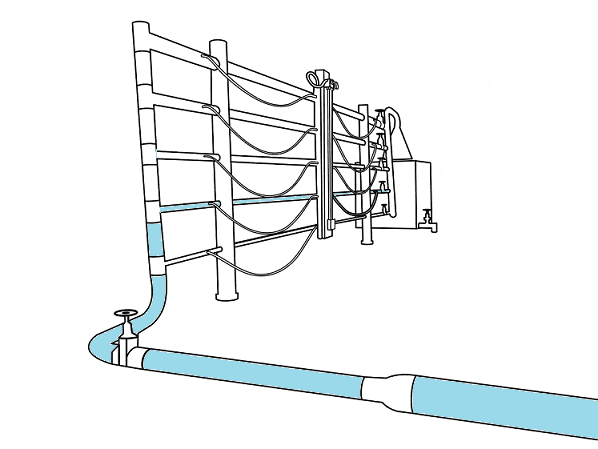

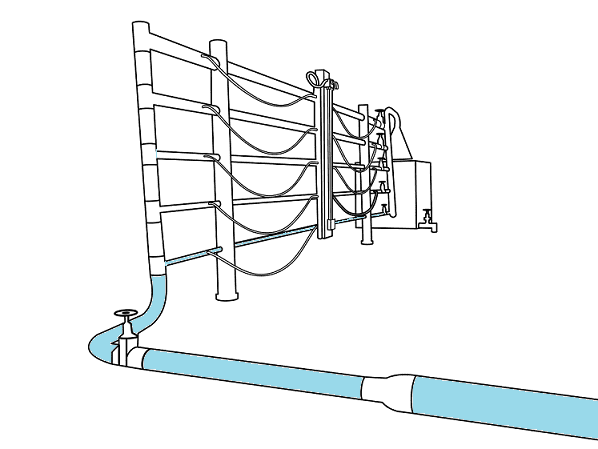

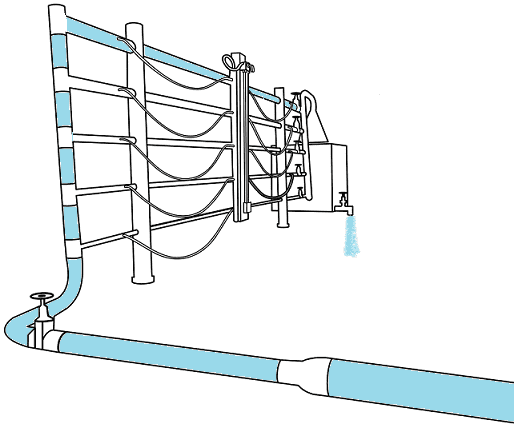

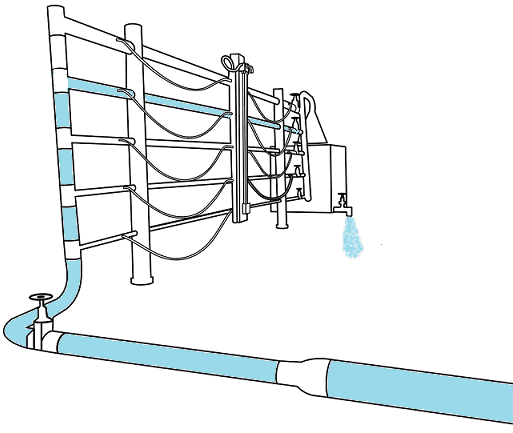

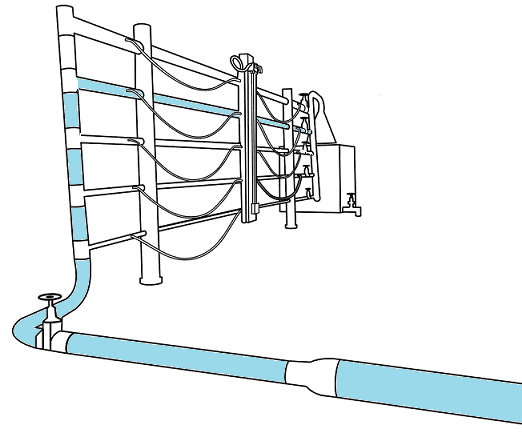

Pipes having different diameter connected to a differential manometer, a collecting tank, stopwatch, scale.

A pipe of the required diameter is selected from the setup.

Except for the selected diameter pipe, the rest of the pipes are closed.

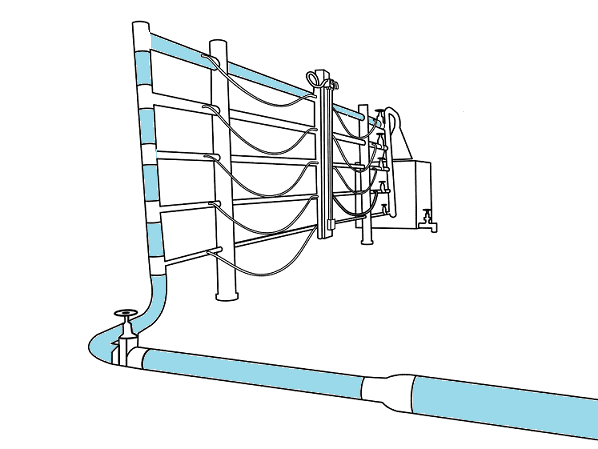

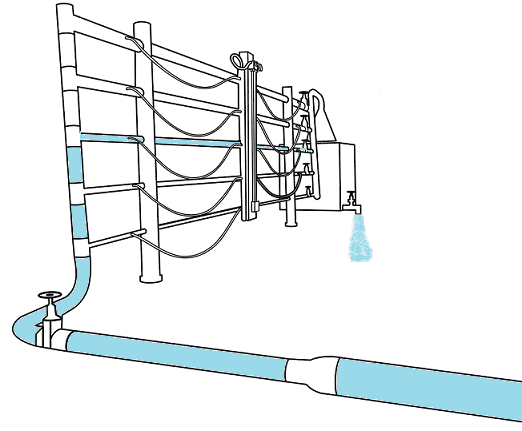

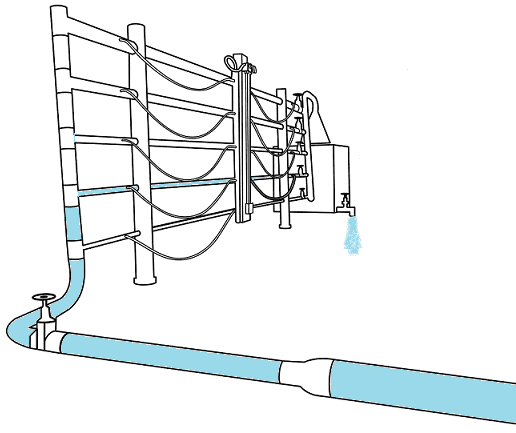

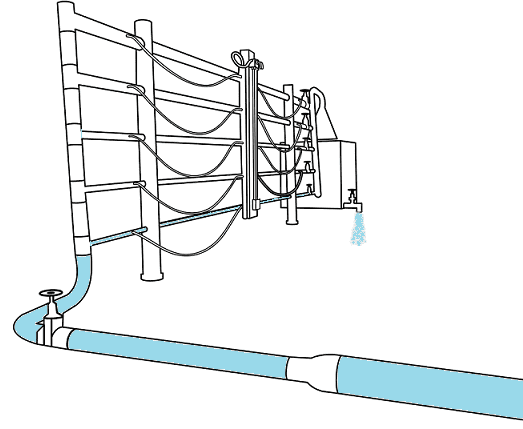

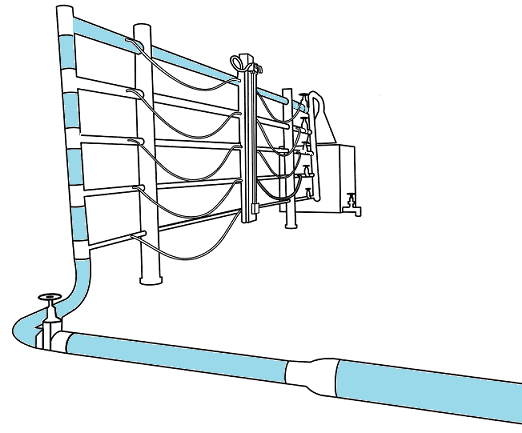

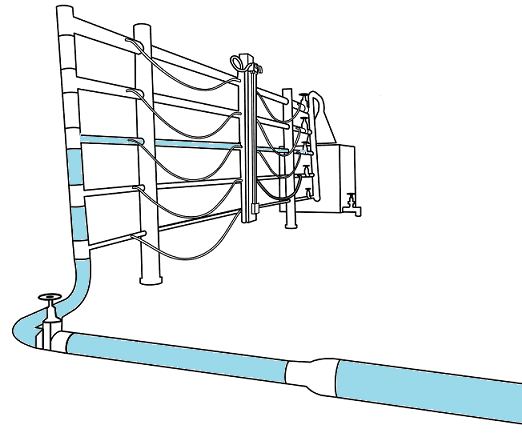

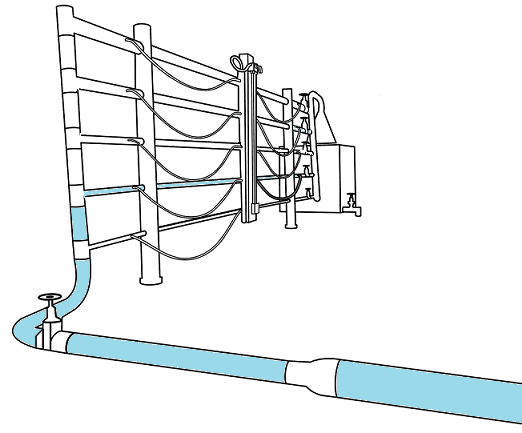

The main inlet valve is opened to allow water to flow through the selected diameter pipe. Open the pipe valve, and change the knot of manometer from isolate position to air-vent position to remove the air inside the pipe.

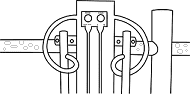

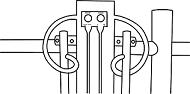

Isolate Position

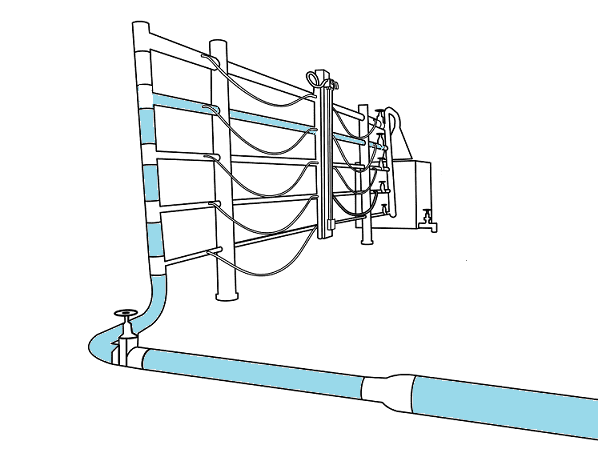

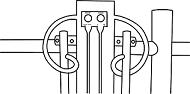

Air-Vent Position

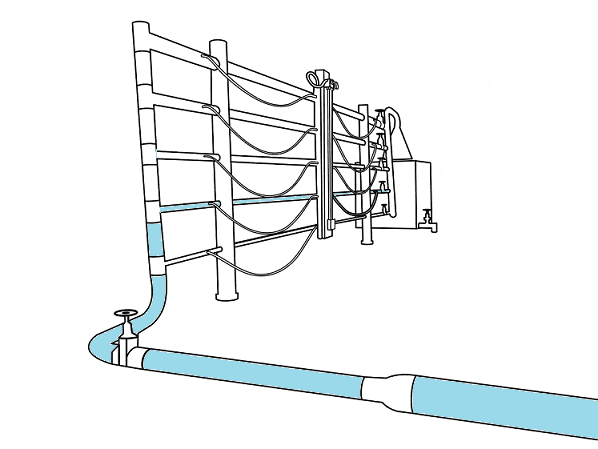

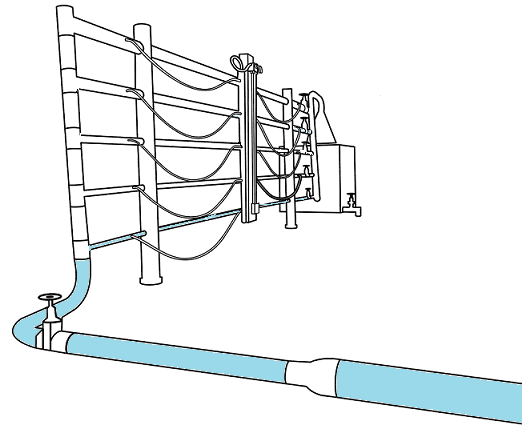

Change the knot to read position when the steady flow is reached inside the pipe. Turn on the exit valve of the collecting tank to allow water flowing inside the pipe to continuously flow out.

Note down the manometer reading.

The exit valve of the collecting tank is closed and time taken for the tank water to rise by 10cm is noted.

Initial reading = 55cm

Final reading = 65cm

Rise (h) = 10cm

Observation

Length of the pipe (l) = 3m

Area of collecting tank (A) = 3500cm2

Rise (h) = 10cm

Acceleration due to gravity (g) = 981 cm/sec2

Calculations

Trial =

CLOSED

CLOSED

CLOSED

CLOSED

CLOSED